In the fast-paced construction era of today, coordination and precision are not a choice but a necessity. Among the numerous technologies transforming the AEC (Architecture, Engineering, and Construction) sector, MEP Modelling is a crucial tool in ensuring design accuracy, smooth execution, and an efficient building solution.

At Genesis Infoserve, we are experts in providing high-quality MEP Modelling services that are specific to the USA market. Whether it’s a commercial high-rise building, hospital, airport, or industrial complex, our MEP professionals ensure that your mechanical, electrical, and plumbing systems are designed and coordinated with maximum accuracy and efficiency.

This definitive guide is designed to assist construction professionals, developers, architects, and consultants in comprehending the significant advantages, procedures, and uses of MEP Modelling in America.

What is MEP Modelling?

MEP Modelling is the production of precise, data-rich 3D digital models of building mechanical, electrical, and plumbing systems. MEP models are different from conventional 2D CAD drawings as they are produced using Building Information Modeling (BIM) software such as Autodesk Revit, enabling stakeholders to see, analyze, and coordinate building services before construction.

The primary goal is to make sure that these systems do not conflict with structural or architectural components, resulting in fewer mistakes during implementation and a more efficient project life cycle.

Why MEP Modelling is so Important for USA Projects

The building industry in the USA is regulated by rigorous standards, intricate building codes, and strict safety protocols. Delays and design failures can cause huge cost overruns and non-compliance.

Here’s why MEP Modelling is not to be parted with:

- Code Compliance: Building codes at the local and state level demand stringent compliance, particularly in fire safety, HVAC planning, energy usage, and electrical layouts. MEP models are designed to meet compliance requirements from day one.

- Energy Efficiency: With green mandates growing, energy modelling via MEP models are designed to meet compliance requirements from day one.

- High Design Complexity: Airport, hospital, and university projects require meticulous coordination of mechanical, electrical, and plumbing systems across disciplines. MEP modelling makes it possible.

At Genesis Infoserve, we provide MEP Modelling solutions with compliance to both local codes and international standards to ensure successful project delivery.

Core Elements of MEP Modelling

1. Mechanical Systems (HVAC):

Our models consist of comprehensive HVAC configurations, ductwork, diffusers, air handlers, chilled water pipes, heating systems, and ventilation zones. They are designed based on precise heating and cooling load calculations to maximize space utilization and optimize energy efficiency.

2. Electrical Systems:

We develop detailed power distribution layouts, lighting systems, emergency power, fire alarms, and low-voltage systems. The models also take into consideration circuiting, panel schedules, and voltage drops to make the designs a true reflection of the performances.

3. Plumbing Systems:

From drainage and water supply to stormwater system and gas piping, our MEP Modelling delivers plumbing designs that meet codes, are accurate, and also save space.

Key Features of MEP Modelling by Genesis Infoserve

As a name to reckon with when it comes to BIM solutions, we offer MEP Modelling services that extend beyond 3D visualization. Here’s why our solutions stand out:

1. Multi-Disciplinary Coordination

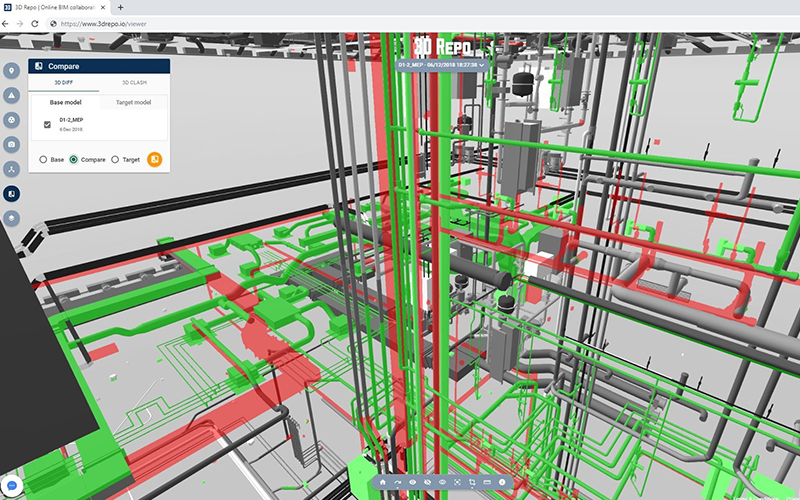

We combine architectural, structural, and MEP models to detect and fix clashes before construction. This saves time, generates fewer RFIs, and reduces rework.

2. Fabrication-Ready Models

We can create our MEP models to LOD (Level of Development) 400 or 500, which gets them fabrication-ready. Contractors can directly utilize these models to fabricate ductwork, pipes, and electrical panels.

3. Code-Driven Design

We integrate U.S. building codes like NFPA, NEC, ASHRAE, IPC, and local amendments into each MEP Modelling project. This helps to maintain compliance without sacrificing design integrity.

4. Data-Rich BIM Integration

Every component in our MEP model has detailed information, material details, manufacturer information, capacity, size, maintenance schedule, and more, aiding long-term facility management.

5. Cloud Collaboration and Version Control

We leverage tools such as Autodesk BIM 360 and Navisworks to enable real-time collaboration, version management, and issue resolution. This keeps everyone involved, from the designer to the site engineers, on the same page.

MEP Modelling Process at Genesis Infoserve

Our MEP Modelling process is streamlined to provide accuracy and efficiency at every step:

Step 1: Requirement Gathering & Design Input

We begin with the collection of architectural and structural plans, as well as design intent drawings for the mechanical, electrical, and plumbing system.

Step 2: Initial Model Development

With software such as Revit, we create 3D models of all the MEP components. In this phase, we concentrate on precise placement, routing, and connection.

Step 3: Clash Detection & Resolution

We perform coordination checks with Navisworks to identify clashes. Interferences are fixed by our team of professionals via coordination meetings and design revisions.

Step 4: Final Model & Documentation

After coordination, we complete the model and create construction-ready documents such as shop drawings, spool drawings, and BOMs (Bill of Materials).

Step 5: Ongoing Support

We provide support to clients throughout construction and after handover, providing model updates, as-built drawings, and facility management assistance.

Industries We Serve

Genesis Infoserve provides MEP Modelling services to various industries in the USA:

- Healthcare Centers

- Schools and Universities

- Commercial Towers

- Residential Complexes

- Industrial Factories

- Retail Outlets

- Transportation Terminals (Airports, Metro Stations)

Every industry has its own design problems and regulatory requirements, and our team makes sure that each model is customized to address those specific needs.

Advantages of MEP Modelling

- Lower Construction Costs due to optimized layouts and least wastage of materials

- Shorter Project Timelines with lower delays and efficient coordination

- Enhanced Safety & Code Compliance with code-based design

- High-Quality Documentation for construction and permitting

- Better Building Performance through energy-efficient infrastructure

- Improved Facility Management with digital twins for future maintenance

Why Genesis Infoserve?

Our MEP Modelling solutions are supported by years of industry experience, global delivery options, and a customer-centric focus. Here’s why construction professionals from the USA trust us:

- Specialist MEP engineers & BIM experts

- Experience with U.S. codes and standards

- Competitive delivery times

- Personalized project solutions of any size

- From design to FM, end-to-end BIM services

We model systems, but we engineer smarter, coordinated, and more cost-effective building solutions that endure.

In the intricate world of construction, MEP Modelling is not a trend, it’s a need. Precise, smart, and coordinated MEP designs are the core of any contemporary building. At Genesis Infoserve, we present you with the expertise, software, and experience you require to succeed with your project, on schedule, on budget, and in a big way.

If you’re planning a project in the USA and want to streamline your MEP systems for maximum efficiency, compliance, and performance, MEP Modelling with Genesis Infoserve is the smart way forward.